neoprene tote proto type

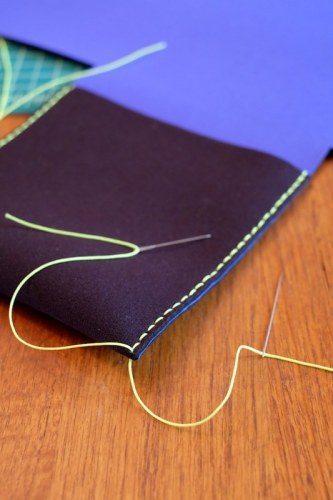

not so much a tutorial for this one- more like field notes. so many hours, mistakes, complications and frustrations. the neoprene is 2mm thick, cobalt on the exterior and black on the interior. the pieces are stitched together with 1mm chinese cord, to look chunky and prominent against the thick neoprene. cord this thick can't be sewn with a machine, so the bag was stitched by hand.

hand stitching:

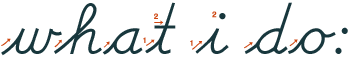

the fabric on both sides of the foam is very tightly woven, which makes it unfriendly to threaded needles. the stitch lines were punched with a leather punch set, and then additionally, each hole was widened with an awl. this was the only way to keep the holes visible in the spongy foam. it wasn't ideal. all stitches were sewn with 2 needles, which looks like this:

handles:

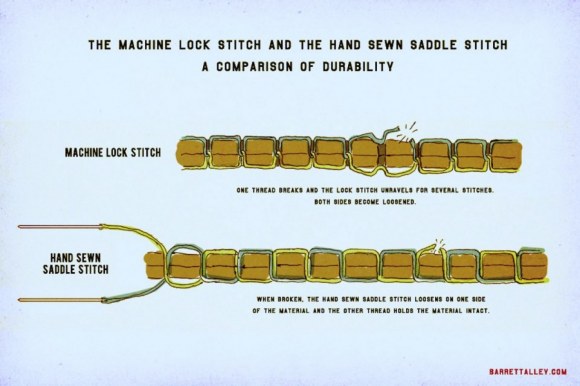

for durability and reinforcement, the handles had to be doubled.

the inner strap is a uniform width, and the outer strap is twice as wide where it's pinched. the pinched portion has a blanket stitch along the edge to keep it securely closed. attaching the straps was a nightmare- the holes on the inner and outer straps had to line up perfectly with the holes on the body. this was really difficult because due to the visibility of the holes. in the end, it took pinning the holes together through all three layers to keep them straight.

interior pocket:

the interior pocket is simply a piece of neoprene folded up on itself and stitched along the sides. the whole thing was stitched to the back panel with a rectangle along the top edge.

side seams:

to reinforce the side seams, a fusible strip was used to attach the front to the back. this is what they use to make wet suits waterproof. in theory, i hoped it would secure the pieces together so they could be punched through all thicknesses at the same time, but that didn't really work.

at the bottom of each side seam is a T seamed gusset. once the seam was finished, the extra fabric was trimmed and a fusible strip was pressed to cover the seam allowance.

verdict:

it's really cute and the perfect size, but not structurally stable. 3mm neoprene will be more functional, but also further complicate punching holes. there has to be a better way to get these holes punched. the space between the top of the bag and the handle pinch is another weak point. i'm still going to wear test this guy while trying to resolve the other issues- hopefully there will be some epiphanies before the 3mm neoprene arrives...